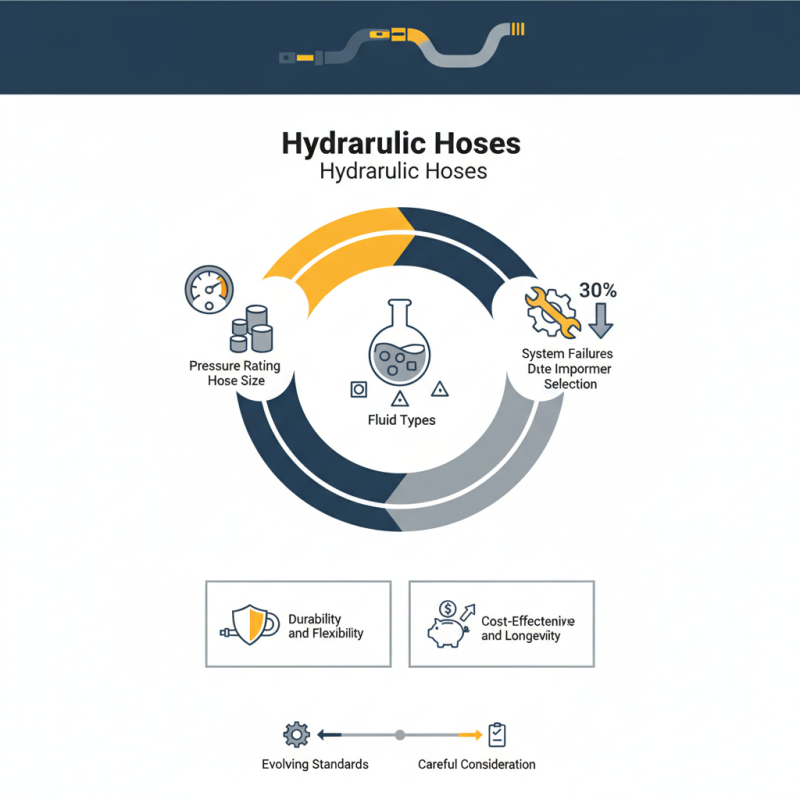

In the hydraulic industry, choosing the right hydraulic hose for sale can significantly impact performance and safety. According to a recent report by the Hydraulic Manufacturers Association, improper hose selection leads to 30% of hydraulic system failures. Expert John Smith emphasizes, “Quality and compatibility are crucial when selecting a hydraulic hose.” His words highlight the intricacies of this industry.

Various factors influence the selection process. Consider pressure ratings, hose size, and fluid types. A mismatch can incur costly downtime. The plethora of options available might be overwhelming. Specific needs can often be overlooked in the quest for low prices. Selecting the wrong type can cause leaks or even catastrophic failures.

Industry standards evolve continuously. Keeping up with those changes is essential for maintenance professionals. Experts recommend considering durability and flexibility alongside pricing. A well-chosen hydraulic hose significantly contributes to system longevity. Thus, clear understanding and careful consideration are necessary. The market for hydraulic hose for sale is competitive, and informed decisions can lead to long-term success.

Hydraulic hoses are crucial components in various machinery. They transport fluid under pressure, enabling systems to function smoothly. Understanding the types and applications of hydraulic hoses can help you make informed decisions.

There are three main types: rubber, thermoplastic, and metal braided hoses. Rubber hoses are flexible and resistant to wear. They suit several applications, including construction and agricultural equipment. Thermoplastic hoses are lightweight and offer excellent chemical resistance. Metal braided hoses are more durable but less flexible, ideal for high-pressure environments.

Choosing the right hose requires consideration of several factors. Think about the hose's diameter and length. It must fit your application without causing pressure loss. Also, consider the working pressure and temperature range. Not all hoses can handle extreme conditions. It's easy to overlook these details, yet they are essential for safety and performance. Make sure to consult specifications to avoid mistakes.

| Type of Hydraulic Hose | Pressure Rating (PSI) | Temperature Range (°F) | Common Applications |

|---|---|---|---|

| Rubber Hydraulic Hose | 5000 | -40 to 250 | Construction, Agriculture |

| Thermoplastic Hydraulic Hose | 4000 | -40 to 212 | Mobile Equipment, Robotics |

| Wire Braided Hydraulic Hose | 6000 | -40 to 250 | Industrial Machinery, Oil & Gas |

| Spiral Hydraulic Hose | 6000+ | -40 to 250 | Heavy Equipment, Forestry |

When selecting the best hydraulic hose, several key factors play a crucial role in your decision. The material of the hose often determines its durability and flexibility. For instance, rubber hoses tend to be more adaptable, while steel-reinforced hoses are better for high-pressure applications. According to industry statistics, up to 30% of hydraulic system failures can be attributed to poor hose selection, highlighting the importance of this factor.

Another critical consideration is the hose's pressure rating. Always ensure that the chosen hose can handle the operational pressures of your system. A hose with a lower pressure rating may lead to catastrophic failures. It's essential to consult pressure charts and select hoses that exceed your typical operating conditions. Keep in mind that the environment where the hose will be used also matters. Factors like temperature extremes and exposure to chemicals can degrade the materials over time.

Tips: Always check compatibility with fluids. Not all hoses work with every hydraulic fluid. Furthermore, think about the length of the hose. Too long can lead to pressure drops. Sometimes, it’s easy to overlook these details, but they are vital for safety and efficiency. Don’t underestimate the cost of a poorly chosen hose—repairs can be expensive. Take your time, do a thorough assessment, and make an informed choice for your hydraulic system.

When choosing the best hydraulic hose, material selection is crucial. The most common materials are rubber, thermoplastic, and metal. Rubber hoses are widely used due to their flexibility and durability. They can withstand high pressure and temperatures, making them suitable for various applications. However, rubber can degrade when exposed to certain chemicals or UV light. This can lead to unexpected failures.

Thermoplastic hoses offer some advantages over rubber. They are often lighter and more resistant to abrasion. This makes them easier to handle and less likely to wear out quickly. However, they may not perform as well under extreme temperatures. Additionally, thermoplastic can be less flexible than rubber, limiting its use in tight spaces. Consider your working environment carefully.

Metal hoses are the most robust choice for extreme conditions. They can handle high pressures and temperatures effectively. Yet, their rigidity can be cumbersome. Installing metal hoses often requires specialized fittings. This can increase installation time and costs. It's vital to weigh these factors when selecting the right hose for your needs. Each material has strengths and weaknesses. Reflecting on your specific requirements is essential before making a decision.

When selecting the right hydraulic hose, sizing and pressure ratings are crucial. A hydraulic hose must match the application it serves. The inner diameter is essential for flow rates. Too small and the system may struggle. Too large can result in inefficient operation. It’s a balancing act that requires careful measurement.

Pressure ratings are equally important. Every hydraulic system operates under specific pressures. Choosing a hose that cannot handle these pressures is risky. It may burst or leak. Always check the specs against your system’s requirements. Over time, wear and tear can reduce a hose's effectiveness. Regular inspections can help catch issues early.

Sometimes, the specifications are not clear. It leads to errors in selection. Understanding how pressure ratings and sizing impact performance is vital. If in doubt, consulting with experts can clarify choices. Selecting the wrong hydraulic hose can be costly. Finding the right fit may take time and effort, but it’s worth it for safe and efficient operations.

Hydraulic hoses are essential for machinery and equipment. Proper maintenance extends their life significantly. Regularly inspecting hoses can prevent failures. Leaks or cracks are warning signs. Sometimes, issues are not visible. According to a recent industry report, poorly maintained hoses can result in 30% of costly downtime.

Proper storage is equally important. Hoses should be kept in a cool, dry place. Avoid exposing them to extreme temperatures. This can lead to deterioration over time. Additionally, methods like regular cleaning can remove debris. A clean hose is less likely to suffer from blockages. Remember, damaging hoses costs money.

Using the correct hydraulic fluid is key. Incompatible fluids can corrode materials. A study indicated that almost 40% of hose failures result from fluid issues. Regular fluid checks may catch potential problems early. By focusing on these maintenance strategies, the lifespan of hydraulic hoses can be more predictable. Always question whether you are doing enough for your equipment.